The Ultimate Guide to NSF 61 Epoxy: Unveiling the Secrets of Safe and Sustainable Coatings

TL;DR

NSF 61 epoxy coatings provide a safe, durable, and sustainable solution for protecting surfaces in contact with drinking water and other sensitive environments. Certified to meet strict safety standards, these coatings ensure no harmful chemicals leach into the water, offering peace of mind and environmental benefits. Ideal for various industries, NSF 61 epoxy excels in water treatment, food processing, healthcare, and more, thanks to its chemical resistance, versatility, and longevity. With proper application and care, these coatings extend the lifespan of structures and minimize maintenance needs, making them a smart choice for applications prioritizing safety, performance, and sustainability.

Introducing the ultimate guide to NSF 61 epoxy – your key to unlocking the secrets of safe and sustainable coatings. In this comprehensive article, we will delve into the world of NSF 61 epoxy, exploring its numerous benefits and shedding light on how it ensures both safety and sustainability, alongside advancements like Weston PowderCoat™ (WPC) and Weston NanoCoat™ (WNC) .

With a maximum word count of 160, we’ll cover everything you need to know about NSF 61 epoxy, from its definition and significance to its applications and recommended usage. If you’re in the market for high-quality coatings that meet strict industry standards, then you’re in the right place.

Our aim is to provide you with accurate and reliable information, enabling you to make informed decisions when it comes to selecting the most suitable coatings for your project. Whether you’re a contractor, engineer, or simply someone interested in the world of coatings, this guide is a must-read.

So, let’s dive deeper into the realm of NSF 61 epoxy and discover how it can transform your coating experience, all while prioritizing safety and sustainability. Get ready to uncover the secrets of this remarkable coating solution.

Understanding NSF 61 Certification

NSF 61 certification and approval is a crucial factor to consider when selecting coatings. This classification ensures that coatings meet the strict safety and health requirements for use in contact with drinking water. NSF 61 certification and approval guarantees that the coating is non-toxic and doesn’t leach harmful chemicals into the water supply.

To obtain NSF 61 certification or approval, coatings must undergo rigorous testing and evaluation. This includes assessing the coating’s chemical composition, durability, and resistance to corrosion. Only coatings that meet or exceed the stringent requirements set by the certification process receive the NSF 61 stamp of approval.

Choosing NSF 61-certified coatings not only ensures the safety of drinking water but also demonstrates a commitment to environmental sustainability. By opting for coatings that meet these high standards, you contribute to the preservation of water quality and the overall well-being of communities.

Importance of Safe and Sustainable Coatings

Safe and sustainable coatings play a vital role in various industries, including infrastructure, manufacturing, and healthcare. These coatings provide a protective barrier that extends the lifespan of structures, equipment, and surfaces, while also minimizing environmental impact. Using safe and sustainable coatings is crucial for protecting both human health and the environment. Traditional coatings often contain harmful chemicals, such as volatile organic compounds (VOCs) and heavy metals, which can have adverse effects on human health and contribute to pollution.

In contrast, safe and sustainable coatings, like NSF 61 epoxy, WPC, and WNC, are formulated with low or zero VOCs and are free from hazardous substances. These coatings not only provide excellent protection but also contribute to a healthier and more sustainable future.

By choosing safe and sustainable coatings, you not only protect the health of those who come into contact with the surfaces but also reduce the negative impact on the environment. It’s a win-win situation that promotes both safety and sustainability.

Advantages of NSF 61 Epoxy Coatings

NSF 61 epoxy coatings offer numerous advantages that make them an ideal choice for various applications. These coatings are highly durable, providing excellent resistance to wear, abrasion, and chemicals. They can withstand harsh conditions, making them suitable for use in industries such as food processing, water treatment, and pharmaceuticals.

One of the key advantages of NSF 61 epoxy coatings is their ability to adhere well to different surfaces, including concrete, metal, and wood. This versatility allows for a wide range of applications, from flooring and tanks to pipes and equipment.

Additionally, NSF 61 epoxy coatings offer excellent corrosion protection, preventing the degradation of structures and equipment over time. This extends their lifespan and reduces the need for frequent maintenance and costly repairs.

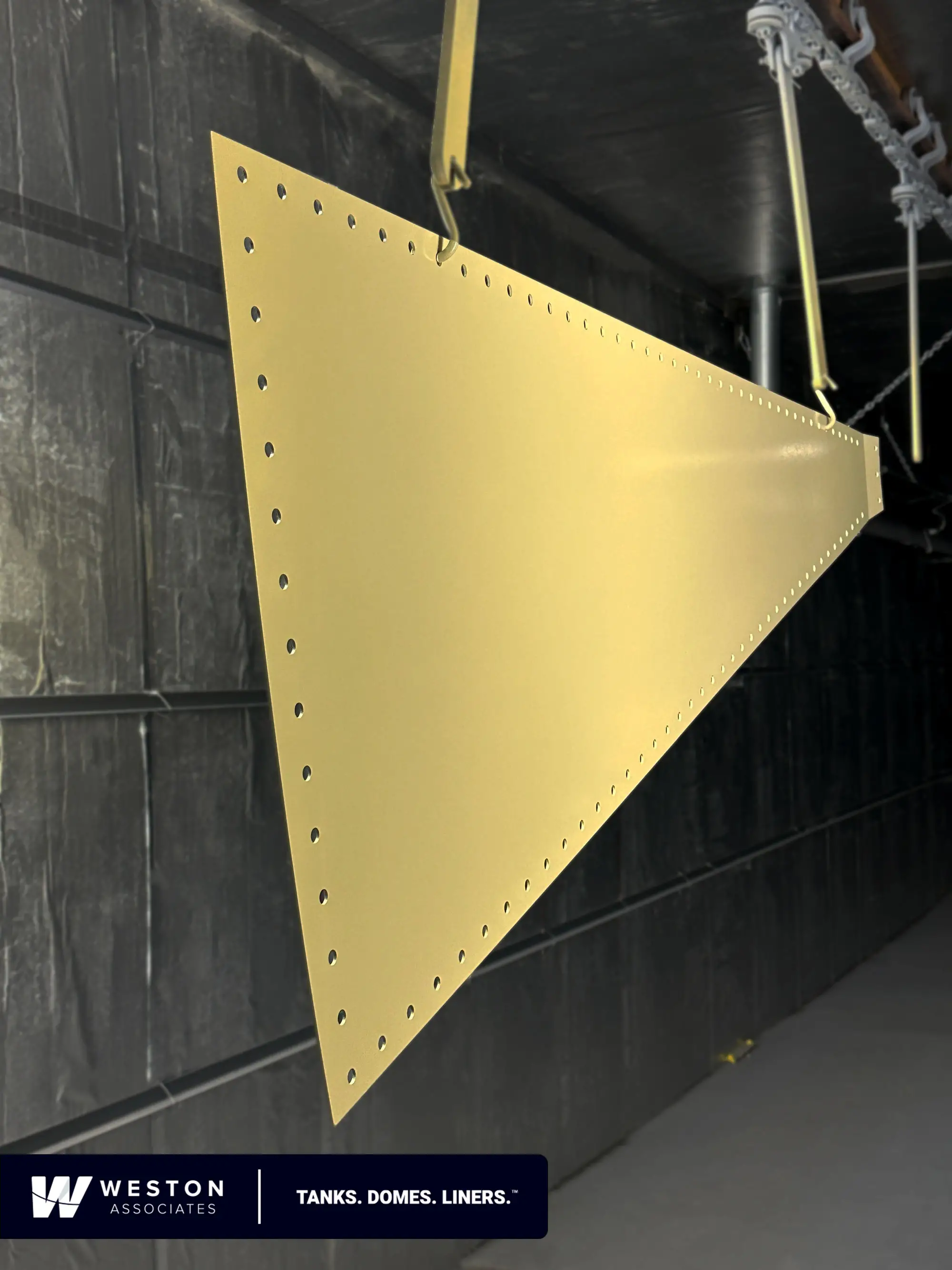

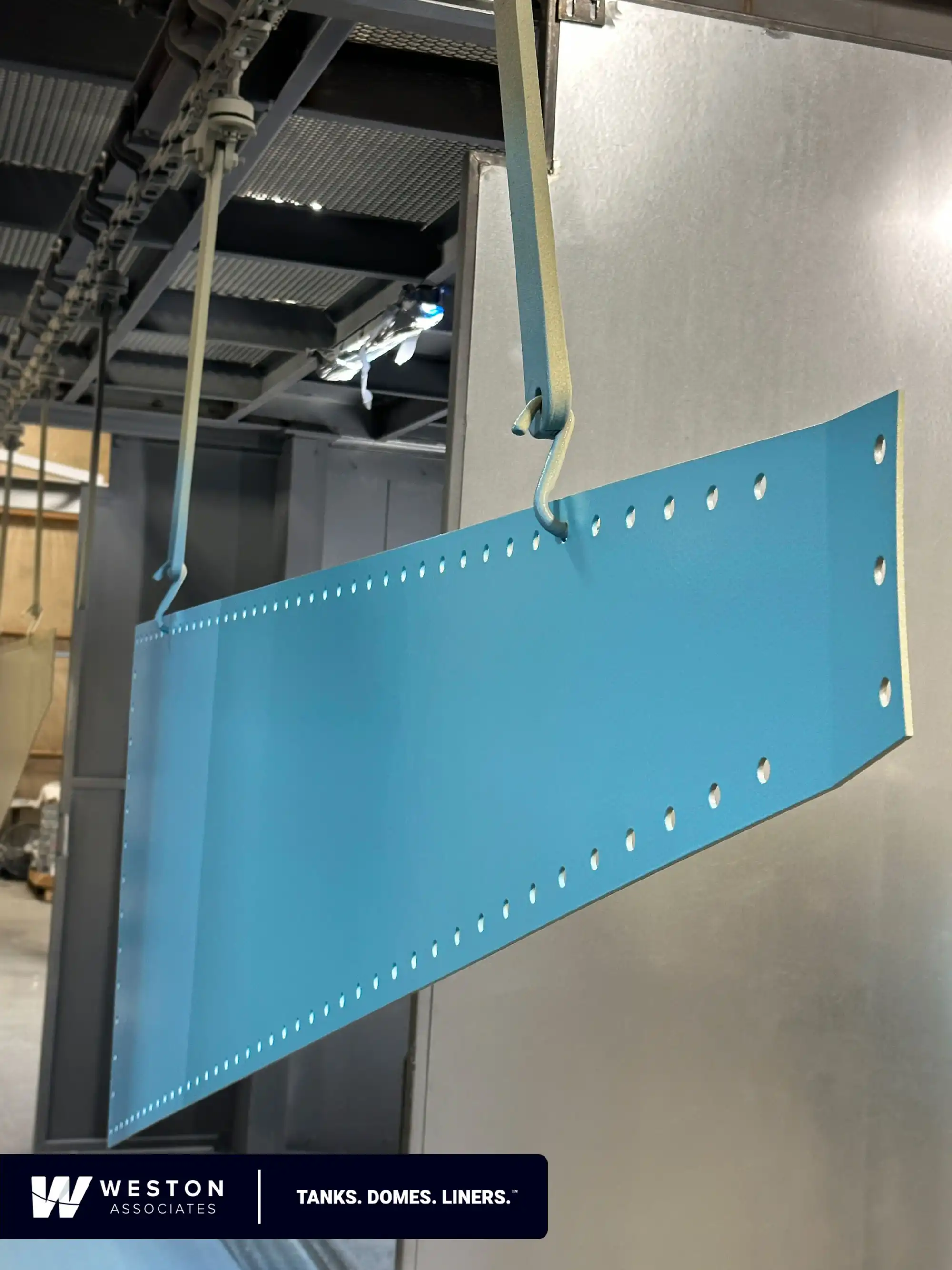

Furthermore, these coatings are available in various colors and finishes, allowing for customization and aesthetic appeal. Whether you’re looking for a glossy finish for a showroom floor or a non-slip surface for a walkway, NSF 61 epoxy coatings can meet your specific requirements.

In summary, the advantages of NSF 61 epoxy coatings include durability, chemical resistance, adhesion to different surfaces, corrosion protection, and customization options. These coatings provide exceptional performance while ensuring safety and sustainability.

Applications of NSF 61 Epoxy Coatings

NSF 61 epoxy coatings find wide-ranging applications in industries where safe and sustainable coatings are required. Here are some of the key applications where these coatings excel:

- Water Treatment Facilities: NSF 61 epoxy coatings are commonly used in water treatment plants to protect tanks, pipes, and equipment from corrosion caused by chemicals and moisture. These coatings ensure the safety and quality of the water supply.

- Food and Beverage Industry: In the food and beverage industry, NSF 61 epoxy coatings are utilized to create hygienic and easy-to-clean surfaces. They are commonly used in food processing areas, commercial kitchens, and breweries to maintain a safe and sanitary environment.

- Pharmaceutical Industry: NSF 61 epoxy coatings are essential in pharmaceutical manufacturing facilities, where cleanliness and sterility are paramount. These coatings provide a smooth and seamless surface that is resistant to chemicals and contaminants.

- Healthcare Facilities: Hospitals, clinics, and laboratories rely on NSF 61 epoxy coatings to create clean and durable surfaces. These coatings are used in operating rooms, laboratories, and patient rooms to ensure a safe and sanitary environment.

- Industrial Facilities: From manufacturing plants to warehouses, NSF 61 epoxy coatings are commonly used to protect floors, walls, and equipment. These coatings provide durability, chemical resistance, and easy maintenance, making them ideal for high-traffic areas.

These are just a few examples of the diverse applications of NSF 61 epoxy coatings. Their versatility and performance make them a preferred choice in industries that prioritize safety, durability, and sustainability.

Factors to Consider When Choosing an NSF 61 Epoxy Coating

When selecting an NSF 61 epoxy coating, it’s essential to consider several factors to ensure it meets your specific requirements. Here are some key factors to keep in mind:

- Certification and Compliance: Ensure that the coating has obtained NSF 61 certification and complies with all relevant industry standards. This guarantees that the coating is safe for use in contact with drinking water.

- Performance and Durability: Evaluate the coating’s performance characteristics, such as chemical resistance, abrasion resistance, and adhesion. Consider the specific conditions and requirements of your application to determine the appropriate level of performance.

- Application Method: Consider the application method and equipment required for applying the coating. Some coatings may require specialized equipment or professional installation, while others can be applied using standard tools.

- Curing Time: Take into account the curing time of the coating. Some coatings may require longer curing periods, which can impact project timelines. Consider the urgency of your project and choose a coating that aligns with your schedule.

- Maintenance and Cleaning: Evaluate the ease of maintenance and cleaning required for the coating. Some coatings may require regular maintenance to retain their performance, while others are more low-maintenance.

By considering these factors, you can select an NSF 61 epoxy coating that meets your specific needs and ensures the desired level of safety and sustainability.

How to Properly Apply NSF 61 Epoxy Coatings

Proper application is crucial to achieving the desired performance and longevity of NSF 61 epoxy coatings. Here are some steps to follow for a successful application:

- Surface Preparation: Ensure that the surface is clean, dry, and free from any contaminants, such as oil, grease, or

loose particles. Use appropriate cleaning methods, such as pressure washing or sandblasting, to achieve a clean and smooth surface.

- Priming: Apply a suitable primer to enhance adhesion and ensure proper bonding between the coating and the surface. Follow the manufacturer’s guidelines for the recommended primer.

- Mixing: Thoroughly mix the epoxy coating components according to the manufacturer’s instructions. Use the recommended mixing ratios and ensure proper blending to achieve a homogenous mixture.

- Application: Apply the epoxy coating using a suitable method, such as brushing, rolling, or spraying. Follow the manufacturer’s guidelines for the recommended application technique and ensure even coverage.

- Curing: Allow the coating to cure for the recommended period, taking into account factors such as temperature and humidity. Avoid any foot traffic or exposure to moisture during the curing process.

- Additional Coats: If necessary, apply additional coats of epoxy to achieve the desired thickness and performance. Follow the manufacturer’s guidelines for the recommended number of coats and curing times between layers.

Proper application techniques and adherence to manufacturer’s guidelines are essential for achieving optimal results with NSF 61 epoxy coatings. Following these steps will help ensure a successful and long-lasting coating system.

Maintenance and Care of NSF 61 Epoxy Coated Surfaces

To maintain the performance and longevity of NSF 61 epoxy coated surfaces, regular maintenance and care are essential. Here are some tips to keep in mind:

- Cleaning: Regularly clean the coated surfaces using mild detergents and non-abrasive cleaning methods. Avoid using harsh chemicals or abrasive cleaners that can damage the coating.

- Avoid Impact: Prevent heavy impact or sharp objects from coming into contact with the coated surfaces. Use protective mats or pads in areas where heavy objects are moved or dropped to prevent damage.

- Inspect Regularly: Conduct routine inspections to identify any signs of wear, damage, or deterioration. Address any issues promptly to prevent further damage and maintain the integrity of the coating.

- Recoating: Depending on the specific application and wear and tear, consider recoating the surfaces periodically to maintain their performance and appearance. Follow the manufacturer’s guidelines for the recommended recoating intervals.

By following these maintenance and care practices, you can prolong the life of NSF 61 epoxy coated surfaces and ensure their continued safety and sustainability. Common FAQs about NSF 61 Epoxy Coatings

- Q: What does NSF 61 stand for? A: NSF 61 refers to the standard for evaluating the safety and performance of materials used in contact with drinking water.

- Q: Are NSF 61 epoxy coatings safe for use in food processing areas? A: Yes, NSF 61 epoxy coatings are safe for use in food processing areas as they meet stringent safety requirements for contact with food.

- Q: Can NSF 61 epoxy coatings be applied to concrete surfaces? A: Yes, NSF 61 epoxy coatings adhere well to concrete surfaces and provide excellent protection against corrosion and chemical exposure.

- Q: Are NSF 61 epoxy coatings suitable for outdoor applications? A: Yes, some NSF 61 epoxy coatings are formulated to withstand outdoor conditions and provide long-lasting protection against UV rays and weathering.

- Q: How long does an NSF 61 epoxy coating typically last? A: The lifespan of an NSF 61 epoxy coating depends on various factors, including the specific application, environmental conditions, and maintenance. With proper care, it can last for many years.

- Q: Can NSF 61 epoxy coatings be applied by non-professionals? A: While some NSF 61 epoxy coatings can be applied by non-professionals, it’s recommended to consult with a professional or follow the manufacturer’s guidelines for the best results.

Conclusion: The Future of Safe and Sustainable Coatings

In conclusion, NSF 61 epoxy coatings offer a safe and sustainable solution for various industries. These coatings ensure the safety of drinking water and contribute to environmental sustainability by meeting strict industry standards.

The advantages of NSF 61 epoxy coatings, including durability, chemical resistance, adhesion, and corrosion protection, make them a preferred choice in applications where safety and performance are paramount.

By considering factors such as certification, performance, application method, and maintenance, you can select the most suitable NSF 61 epoxy coating for your specific needs. Proper application techniques and regular maintenance will help ensure the longevity and performance of NSF 61 epoxy coated surfaces.

As the demand for safe and sustainable coatings continues to grow, NSF 61 epoxy coatings are at the forefront of the future of coating solutions. By prioritizing safety, durability, and sustainability, these coatings contribute to a healthier and more environmentally friendly world. Choose NSF 61 epoxy coatings and unlock the secrets of safe and sustainable coatings today.